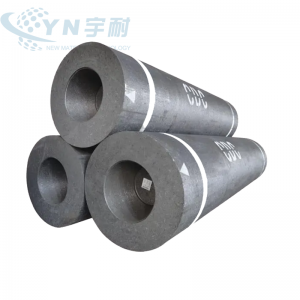

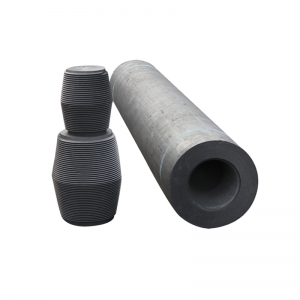

HP Graphite Electrode

Tsarin samar da lantarki na graphite gabaɗaya ya haɗa da: albarkatun ƙasa (ulu) → batching → kneading → extrusion gyare-gyare → babban zafin jiki sintering (1550 ~ 1700 ° C) + maganin zafi (1100 ~ 1200 ° C) + ƙarewa.

1. Wool pretreatment: cire datti a cikin ulu.Babban hanyar ƙazanta ita ce amfani da wankan ruwa ko wanke alkali.

2. Abubuwan da ake buƙata: Ƙara wani adadin yashi quartz lokacin da ake cuɗawa, kuma sanya kayan da aka gauraya a cikin kayan ƙulluwa.

3. Kneading: Sanya albarkatun da aka gauraye a tsakiyar graphite extruder, sa'an nan kuma a kwaɗa da fitar da albarkatun da aka ƙulla don samar da su a cikin ƙirar graphite.

4. Gasasshen: A ƙona kayan da aka haɗa tare da gawayi zuwa jajayen zafi ko abubuwa masu ƙonewa kamar baƙar fata da gawayi, sannan a shiga tsari na gaba.

5. Ƙarshe: Bayan da aka samar da mold, yana buƙatar yanke, welded, gogewa da sauran matakai.

6. Marufi: Dole ne a duba kayan kwalliya (ciki har da tsabta da kuma ko akwai lalacewa da tarkace, da dai sauransu) kuma a jera su a jera su kafin a adana su a cikin ma'ajin.

Ayyukan cajin cajin carbonization sune: don kare cajin daga iskar oxygen a babban zafin jiki, don tabbatar da cewa abubuwa masu ƙarfe a cikin slag ba za su canza ba;don kula da ragi na carbothermal a cikin yanayin narkakkar, don tabbatar da cewa cajin ya narke a mafi kyawun zafin jiki da lokaci.

Babban aikin tanderun baka na lantarki shine gabatar da baka na lantarki a cikin cajin don narkar da narkakkar kayan karfen carbon da aka narkar da shi zuwa garin karfe.A lantarki abu na lantarki baka makera ne gaba ɗaya graphite lantarki, anode da cathode graphite.

Carbonization oven: Ana kona gawayi a cikin tanderun don samar da carbon da oxygen, kuma iskar hayaki da aka samar ya shiga cikin ruwan narkakkar bayan sanyaya, kuma narkakken karfen yana fitar da shi waje a lokaci guda.

Rotary Kiln: Ana amfani da rangwame a cikin aikin narka don narke karafa ko gami.

Quote Now

Quote Now